The Unseen Universe in a Scoop of Milk Powder

We encounter it as a quiet collaborator in our kitchens—an unassuming ingredient listed on high-protein yogurts and baked goods. Milk powder is a cornerstone of the modern pantry, valued for its long shelf life and versatility. Yet behind its simple appearance lies a story of intentional design—a tale of how food science takes one of nature’s most perishable liquids and re-engineers it, particle by particle, into a stable and powerful ingredient. What hidden world of physics, chemistry, and meticulous control is required to transform fresh milk into this fine-grained dust?

This is a journey into that unseen universe. We’ll explore the controlled turbulence of sonic-wave drying, descend into the microscopic architecture of a single powder grain, and discover how this humble ingredient—known as skim milk powder or nonfat dry milk—is used to artfully craft the texture and nutrition of the foods we eat every day. It’s a story of scientific ingenuity, all aimed at capturing the essence of milk in an entirely new and enduring form.

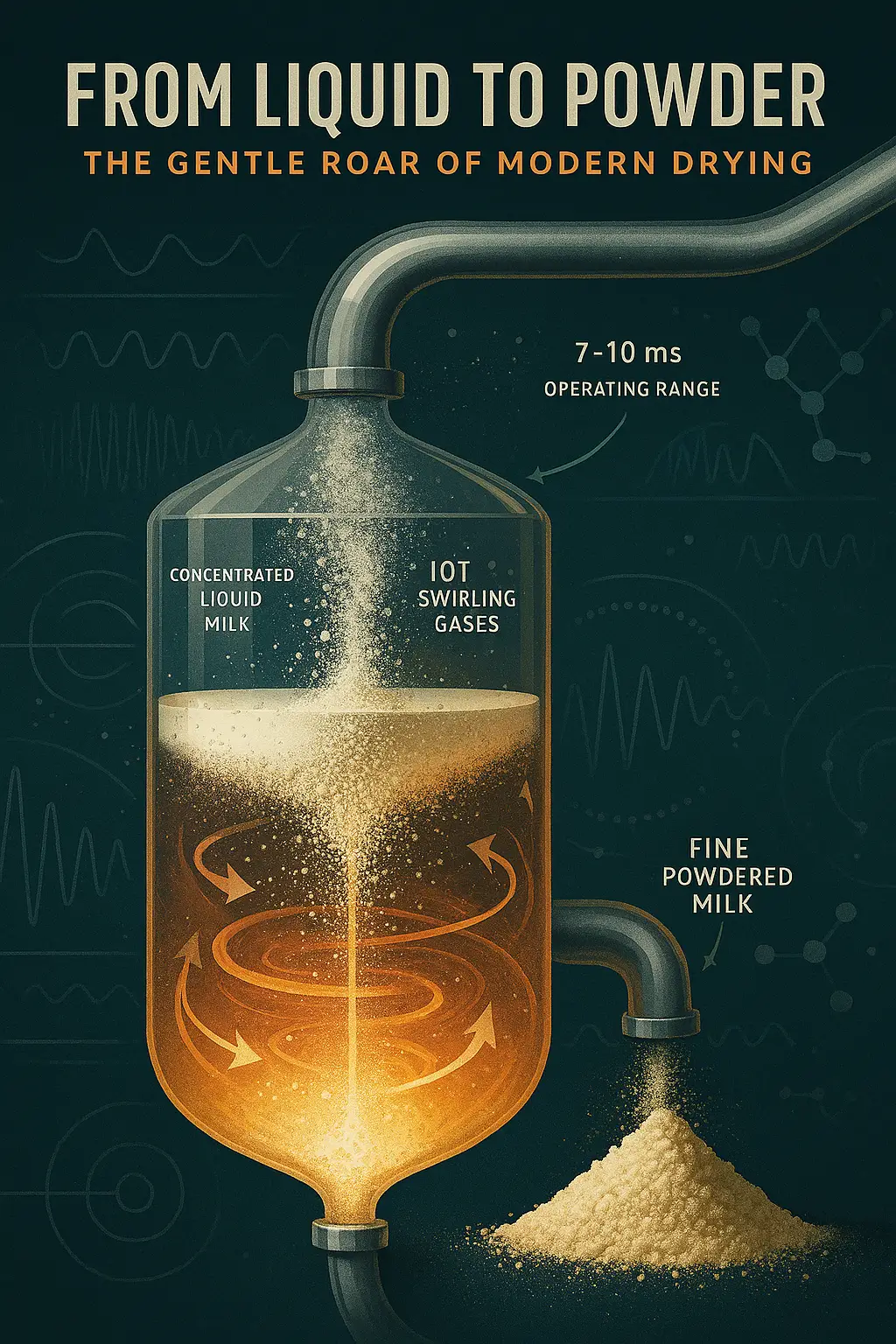

1. From Liquid to Dust: The Gentle Roar of Modern Drying

Turning liquid milk into milk powder is a scientific tightrope walk between preservation and annihilation. The goal is to remove water, yet the process must be gentle enough to protect milk’s delicate proteins and subtle flavor. This is the challenge of performing a radical transformation without sacrificing integrity—and modern food engineering has risen to meet it brilliantly.

At the forefront of this innovation is Pulse Spray Drying (PSD), a more sustainable and efficient leap beyond conventional Spray Drying (SD), long the industry standard. PSD can improve thermal efficiency by up to 40%, but its true genius lies in its speed. Milk droplets are exposed to heat for mere milliseconds—a stark contrast to the several seconds required in traditional systems.

Imagine a concentrated milk liquid injected not into a gentle mist but into the heart of a controlled hurricane. The system ignites a fuel-air mixture, creating pulsating, high-velocity streams of hot gas and sonic waves. This immense force shatters the liquid into a fine aerosol of droplets, drying them almost instantaneously. The astonishing speed allows for higher temperatures without scorching heat-sensitive milk proteins—crucial for maintaining quality.

This technological evolution is about more than efficiency; it’s about creating a fundamentally superior product. The ultra-fast, gentle nature of PSD ensures that native whey proteins—such as α-Lactalbumin and β-Lactoglobulin—are exceptionally well preserved. The process forms skim milk powder that retains more of the original nutritional and functional qualities of fresh milk, shaping a microscopic world that defines its final form.

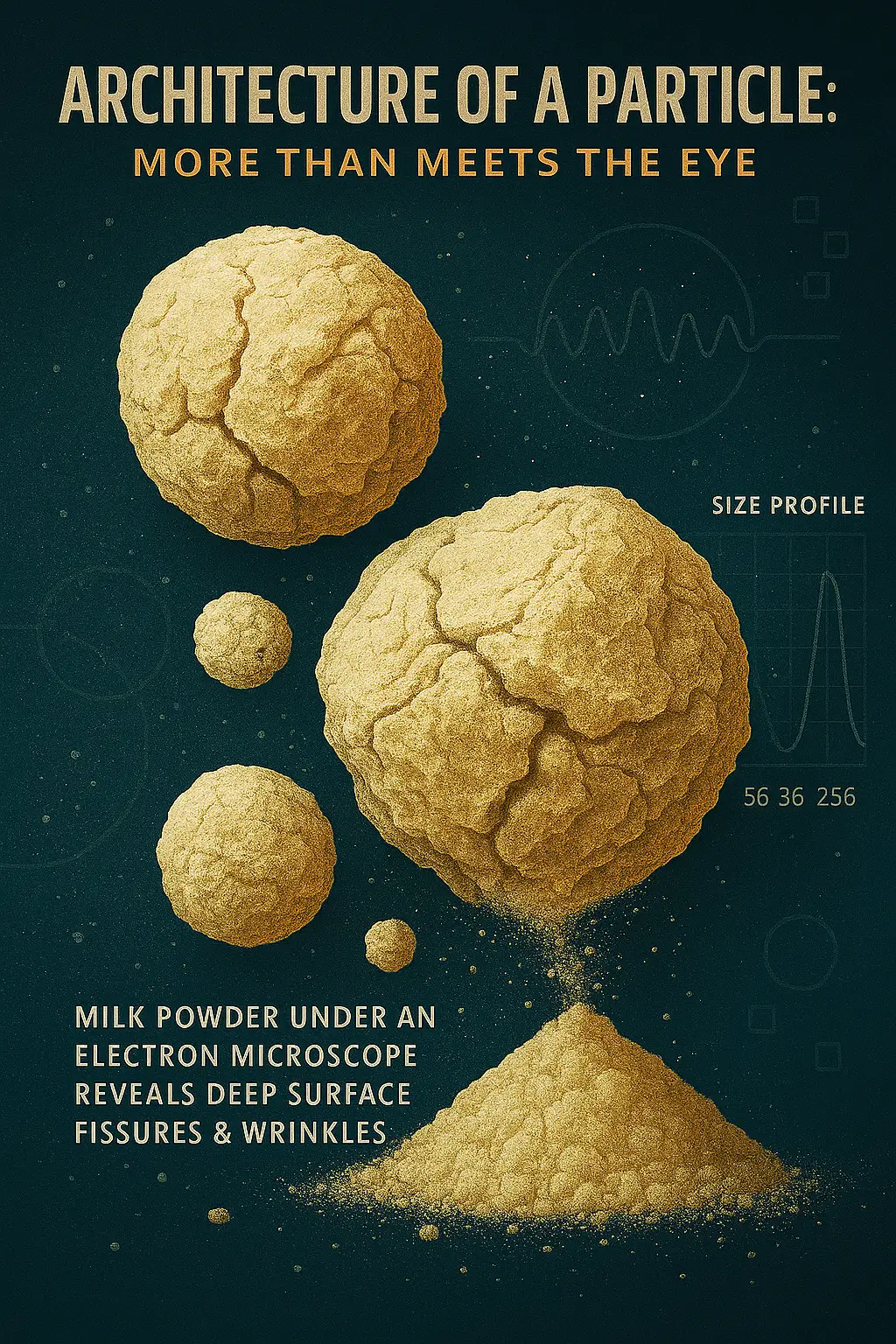

2. The Architecture of a Particle: More Than Meets the Eye

The physical structure of milk powder is no accident. Every feature—from particle size and shape to surface texture—is the direct result of the drying process. This microscopic architecture is deliberately engineered, as it dictates how the powder behaves—whether dissolving smoothly in water or fortifying the texture of yogurt.

A Glimpse into the Microscopic Landscape

Under a scanning electron microscope, milk powder reveals itself not as smooth spheres but as a complex landscape. The particles exhibit “deep and shallow folds with wrinkles on the surface”—a textured finish born of the violent, near-instant evaporation during Pulse Spray Drying. This rapid drying also produces more hollow particles, lowering bulk density. Tiny particles often cling to larger ones—a physical record of their turbulent journey from liquid to solid.

The Functional Impact of Particle Size

Particle size is paramount. Both PSD and SD produce fine powders, but with different distributions. Excess fines can cause poor flow and wetting—explaining why some protein mixes or instant cocoas clump stubbornly instead of blending smoothly.

Here, intentional design makes all the difference. Though both are rated “very poor” in flowability, PSD powder flows nearly twice as fast (19.55 g/min vs. 10.68 g/min) thanks to its narrower, more uniform particle size distribution. This precision engineering minimizes clumping and showcases a sophisticated mastery of relative performance. As one study notes:

“Quality in terms of product, process, and environment in a milk production plant can be measured through performance, reliability, and durability. The quality management system, in whatever form it takes, is the pinnacle of differentiation.”

Ultimately, the physical form of nonfat dry milk is only half the story; its true purpose emerges when it becomes a transformative ingredient.

3. The Artful Enhancer: How a Simple Powder Transforms Our Food

Skim milk powder isn’t merely a substitute for fresh milk—it’s a high-performance functional ingredient. Food scientists use it to engineer precise nutritional profiles and textures in other foods, reshaping them to meet modern demands.

The Transformation of Yogurt

Creating high-protein yogurt is a prime example. Studies show that enriching yogurt with 10% skim milk powder increased its protein content by up to 82%, from 3.50 g/100 g to 6.36 g/100 g. This simple fortification transforms ordinary yogurt into a nutrient-dense food perfectly aligned with today’s wellness trends.

Engineering the Perfect Mouthfeel

The impact of milk powder extends beyond nutrition to texture. The same study found that adding 10% powder more than tripled yogurt viscosity—from 1,295 mPa·s to 4,106 mPa·s. This is texture design in action. The extra milk proteins form a denser, three-dimensional mesh that traps water more effectively, creating the thick, creamy consistency consumers love in Greek-style yogurts.

This process perfectly illustrates how a traditional ingredient can be used scientifically to meet dual demands: foods that are both nutritious and sensorially satisfying. But crafting a product that feels right is only half the challenge—it must taste exceptional, too.

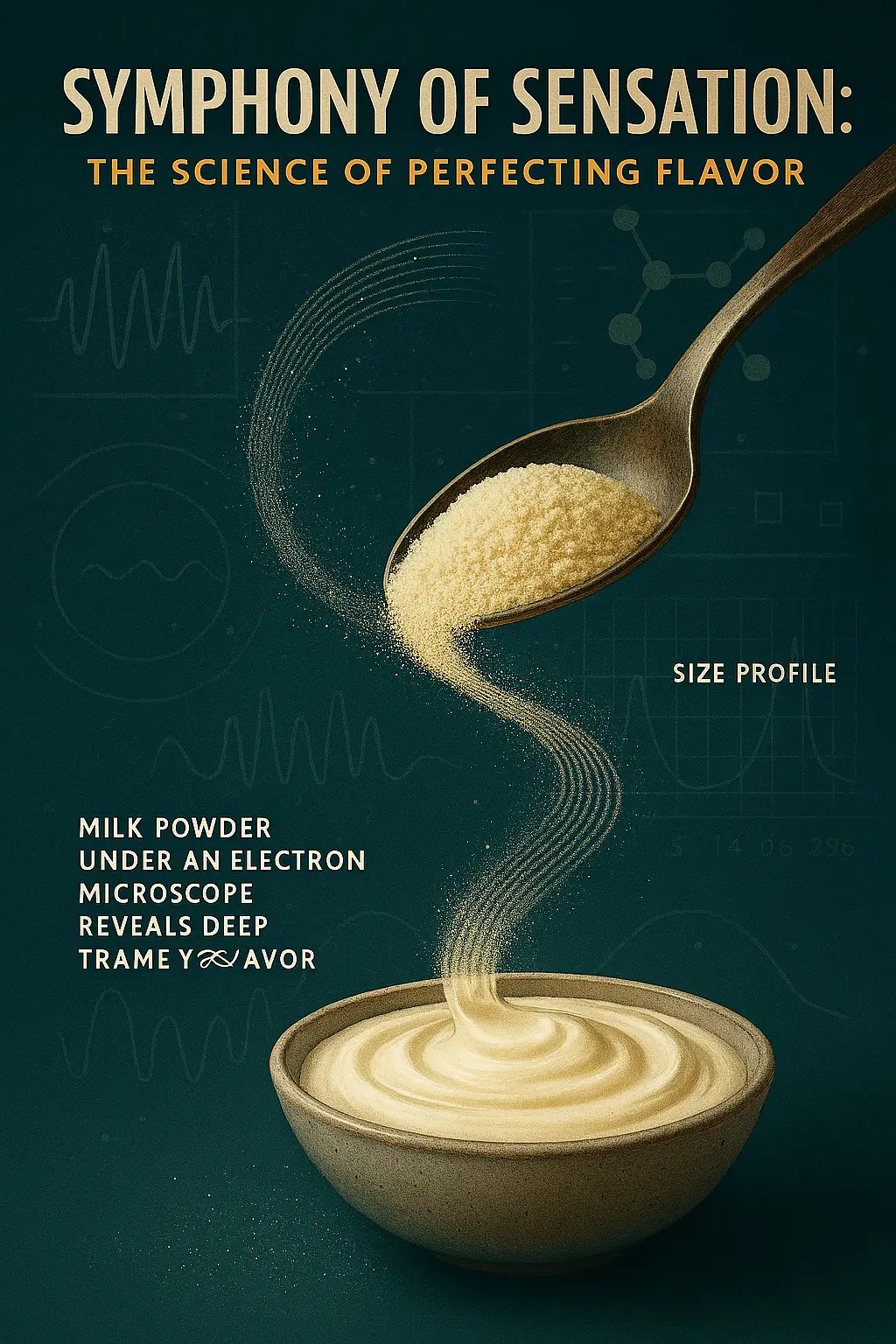

4. A Symphony of Sensation: The Science of Perfecting Flavor

Preserving the fresh flavor of milk through intense drying is a monumental scientific challenge. Food technologists carefully monitor subtle shifts in taste and aroma to ensure every batch of milk powder delivers a consistent, high-quality sensory experience.

The Flavor Challenge

Sensory evaluations reveal the complexity of this task. Experts identify key flavor notes—two of the most important being “cooked” and “flat.” These aren’t necessarily defects; they’re variables that must be controlled. A “cooked” note, arising from heat treatment, is acceptable in extra-grade powders, while a “flat” flavor signals lack of freshness. Managing these is central to quality assurance.

How Fortification Can Enhance Flavor

Remarkably, when used as an ingredient, skim milk powder can enhance flavor. Research on fortified yogurt showed that adding it significantly increased acetoin—a key flavor compound—from 144.90 to 268.56 mg/kg. Acetoin contributes a “pleasant, creamy flavor,” proving that milk powder can not only fortify but also fine-tune and elevate the sensory profile.

A Commitment to Meticulous Oversight

This pursuit of sensory perfection rests on rigorous oversight. Every aspect of the powder’s chemical composition—from moisture and fat to protein—is precisely analyzed. This commitment ensures that whether nonfat dry milk is used today or months later, it performs and tastes exactly as intended. From the physics of drying to the chemistry of flavor, all efforts aim to perfect a product most of us take for granted.

Conclusion: A New Appreciation for the Everyday

From the controlled chaos of Pulse Spray Drying that gently turns liquid into dust to the wrinkled, intricate architecture of every microscopic particle, the story of milk powder is one of remarkable scientific design. We’ve seen how this fine powder is far more than a pantry staple—it’s a high-performance ingredient intentionally crafted to build the nutrient-rich, texturally delightful foods that define the modern diet.

The next time you scoop skim milk powder or spot it on an ingredient label, you may see it differently. Within that fine dust lies a universe of innovation, precision, and care—a powerful testament to the science and craftsmanship hidden in the essentials of daily life.

For More Information Read This Article.